The standard access hatch to the area behind the engine is a plywood panel glued and screwed in situ, with a small plastic screw hatch. It’s not very good. The bigger circular item is a base for a cockpit table. Below this hatch are the cockpit drain seacocks, the gearbox dipstick, the gearbox oil cap, the propeller shaft, the stern gland, the exhaust elbow, the exhaust box, etc, etc. That little screw hatch gives next to no access at all.

Spurred on by a post in the Cornish Crabber forum by Kevin Misselbrook, I decided to follow his lead and add a larger inspection and access hatch. It only took me 30 minutes, so is an easy upgrade for any other owners. Buy the hatch by clicking here.

This is with the plywood hatch removed, and you can see the sten gland and cockpit drain seacocks.

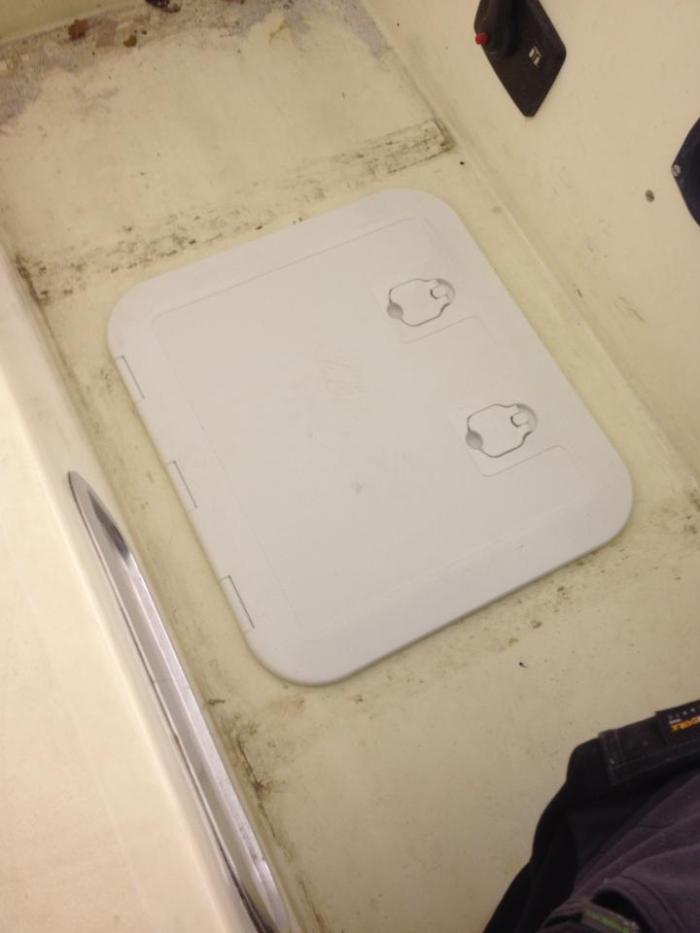

This is the hatch in place. All I needed to do was cut out a slightly larger hole with my jigsaw.

Here the hole has been enlarged and the screw holes for the hatch drilled though,

The hatch now sits flush and just needs loads of sealant underneath, before screwing down tightly.

That’s all there is to it. I wiped the excess sealant away with a rag, and that was it. I then covered it up with the new red cedar duck-boards make by my dad, Tony.

Now that’s a good looking fix.. job’s definitely a good’un, and I like those duckboards to..

Looking good!

If you spray those duck boards, and any other bare wood, with a solution of Brintons Patio Magic they won’t go green. Take another look at Aeolus if you don’t believe me 🙂

Nice hatch but I have enjoyed many meals at the cockpit table.

Hi Mike. I could still fit it, but will wait to see how we get on next year first. It was great to see you today.

I hope you don’t object but I’d like to show my boatwright the pictures when he rebuilds my engine box and cockpit sole. The red cedar looks very good, was it easy to find?

Lloyd – Gilda Mk1

Hi Lloyd, the cedar was readily available at my local joinery. It smells beautiful too!

There is a Cuprinol product called StayNew for garden furniture, I have found this excellent for teak and cedar. It is very easy to apply. I have it on a teak nameplate and it has lasted there for 3 years.

A slight note of caution – the cockpit sole is balsa-cored, so you need to be very sure that no water will leak into your cut edges or screw holes to rot the core. Personally I would have used thickened epoxy to re-encapsulate the wood rather than just rely on the sikaflex under the hatch…